Nickel hydroxide is widely used in electroplating, catalyst preparation, pigments, and ceramic industries.

In many industrial processes, nickel hydroxide needs to be dissolved in weak acid solutions, where dissolution efficiency and operational conditions become critical.

This article introduces the key factors and precautions for dissolving industrial-grade spherical nickel hydroxide in weak acids, helping improve dissolution rate and process stability.

Overview of Industrial-Grade Spherical Nickel Hydroxide

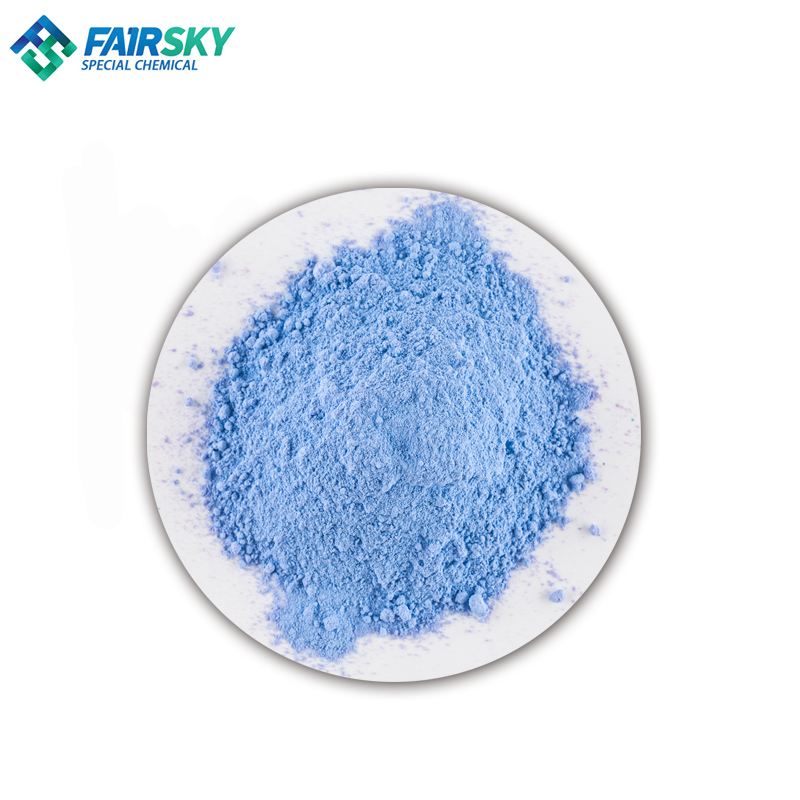

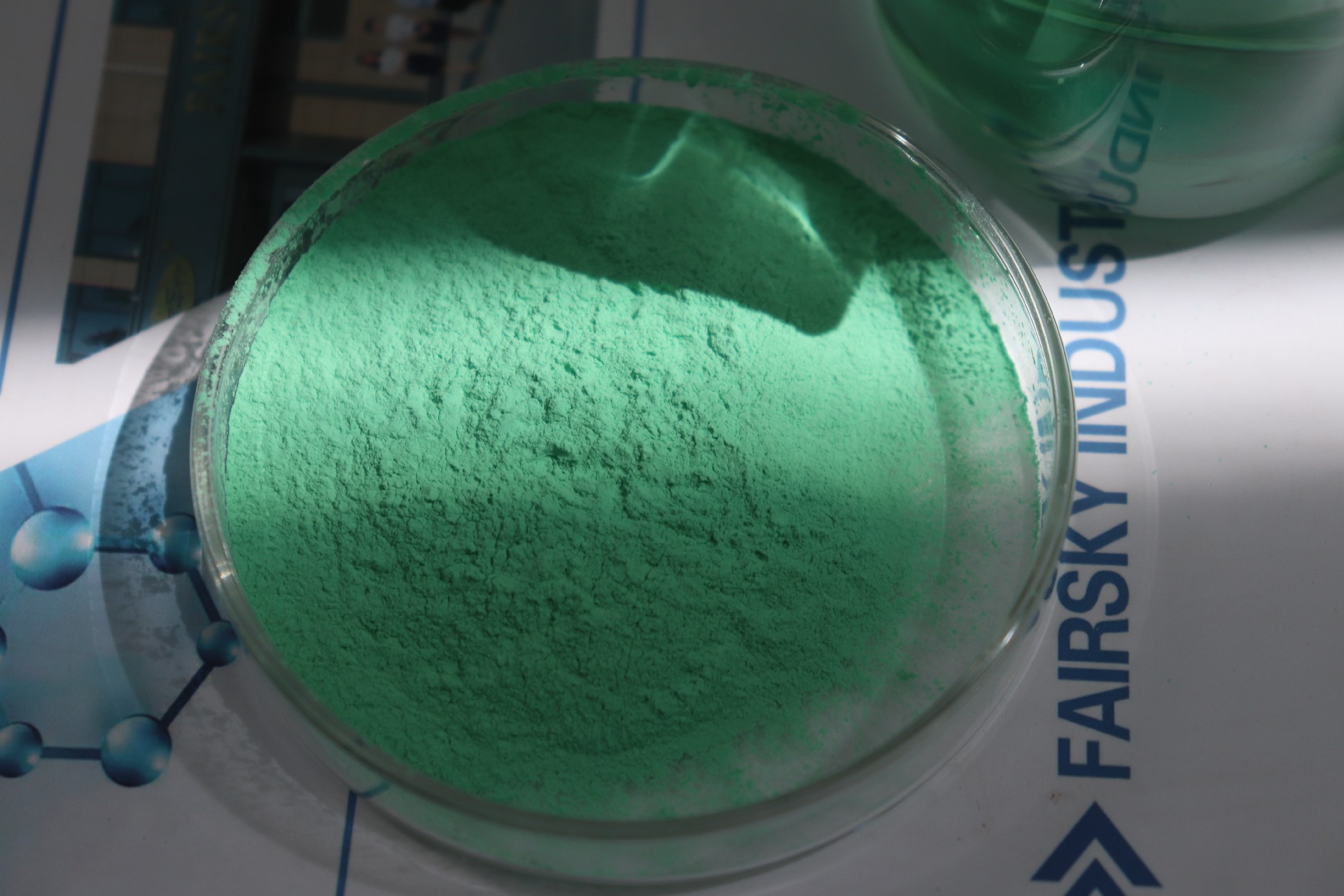

Industrial-grade spherical nickel hydroxide, commonly known as Nickel Hydroxide or Nickel (II) Hydroxide, is typically supplied as a green powder.

Thanks to its spherical morphology, the material exhibits excellent flowability and low agglomeration tendency, which makes it suitable for industrial handling and dosing.

Product Basic Information – Nickel Hydroxide

The following table summarizes the key specifications of Nickel Hydroxide for industrial and chemical applications.

Field | Description |

Product Name | Nickel Hydroxide |

Molecular Formula | Ni(OH)₂ |

CAS No. | 12054-48-7 |

Appearance | Green crystalline powder or fine green powder |

Specification | Ni ≥58%,≥59%,≥61% |

Main Applications | Used as active material for rechargeable batteries (Ni-MH, Ni-Cd); intermediate for nickel salts; catalyst and catalyst carrier; raw material for electroplating and ceramic industries |

Manufacturer | FAIRSKY INDUSTRIAL CO., LIMITED |

Solubility of Nickel Hydroxide in Weak Acids

Nickel hydroxide is soluble in acidic solutions, but its dissolution rate is relatively slow in weak acids compared with strong acids.

In practice, the dissolution behavior is strongly influenced by acid preparation, addition method, stirring intensity, and temperature control.

Key Factors Affecting the Dissolution of Nickel Hydroxide

1. Pre-dissolution of the Weak Acid

Before adding nickel hydroxide, the weak acid should be fully dissolved in water.

This step is essential, as incomplete acid dissolution can significantly reduce the overall dissolution rate of nickel hydroxide.

2. Controlled and Gradual Addition

After the weak acid solution is prepared, nickel hydroxide should be added slowly in small portions while stirring.

A slower addition rate combined with sufficient stirring helps prevent local saturation and promotes more efficient dissolution.

3. Stirring and Temperature Control

Continuous stirring improves mass transfer between solid particles and the acid solution.

At the same time, moderate heating can further accelerate the dissolution process, especially in weak acid systems.

4. Heat Retention and Moisture Control

Heating also increases evaporation.

Covering the container during the dissolution process helps maintain temperature and moisture, creating more favorable conditions for dissolving nickel hydroxide efficiently.

Practical Conclusion

Nickel hydroxide can be effectively dissolved in weak acids when proper operational conditions are applied.

By optimizing acid preparation, addition rate, stirring, and temperature control, the dissolution process becomes more efficient, stable, and predictable for industrial applications.

Applications of Nickel Hydroxide

Nickel hydroxide is widely used in:

Nickel electroplating processes

Industrial catalysts

Pigments

Ceramic materials

| As an experienced supplier of industrial-grade nickel hydroxide, Fairsky provides spherical nickel hydroxide with stable quality, supporting customers in electroplating and catalytic applications. |